The Role of Euro Pallets in Modern Supply Chains

Standardization: The Foundation of Efficiency

The Euro pallet, measuring 1200 by 800 millimeters, really makes life easier for logistics operations. The fact that they're all the same size means everything just fits together better when it comes to moving stuff around warehouses, stacking them neatly, and getting products from one country to another without headaches. Companies save loads of time because their trucks don't sit idle while loading or unloading, plus there's no need to worry about whether equipment will work properly with different sized pallets. Some research shows that sticking to these standards can actually make logistics operations run about 40% faster, which obviously saves money and time in the long run. Another big plus is that workers don't have to learn special techniques for handling different types of pallets. New hires get up to speed much quicker since everyone handles things the same way, and this consistency helps keep operations running smoothly throughout the entire supply chain network.

Why Euro Pallets Outperform Traditional Options

Euro pallets stand out when compared to regular wooden pallets because they simply last longer and handle rougher treatment. Constructed with better quality timber, these pallets can take on much heavier weights without breaking down during transport, which means less damage to goods being shipped. Industry insiders often point out that while standard pallets might only make it through about five years before needing replacement, Euro pallets typically stick around for around ten years or more. Their widespread use across Europe makes them compatible with most logistics systems there, cutting down on delays and headaches throughout the supply chain. From cars coming off assembly lines to delicate medical supplies, companies across various industries have switched over to Euro pallets and noticed real improvements in their day-to-day operations. Take one food manufacturer as an example who saw inventory moving through warehouses 25% faster after making the switch, plus saved roughly 15% on overall shipping expenses.

Key Benefits of Euro Pallets for Logistics Optimization

Enhanced Space Utilization in Transport and Warehousing

Euro pallets are designed to make better use of space inside trucks and warehouses because they balance loads more effectively. Measuring 1200mm by 800mm, these standard sizes fit neatly into most transport vehicles and storage areas, meaning businesses can move more products at once than with older pallet designs. Some companies report being able to carry around 30% more stuff when switching to Euro pallets, which obviously cuts down on shipping expenses and what it costs to store inventory. The extra room also means less fuel burned during transport and smaller carbon footprint overall, something many businesses care about these days as they try to operate in a greener way without sacrificing efficiency.

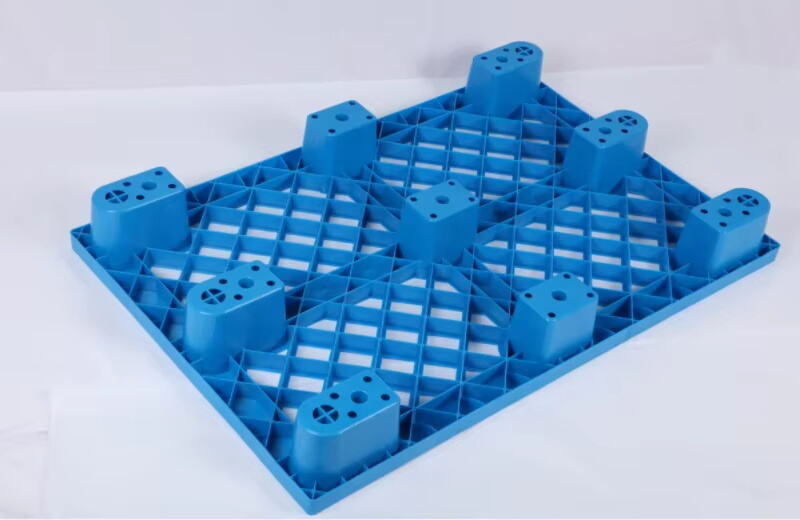

Reduced Product Damage Through Superior Load Stability

Euro pallets really stand out when it comes to keeping loads stable, which cuts down on product damage while things are being transported. Made with solid materials like durable wood or plastic composites, these pallets give goods a firm base that stops them from moving around so much during shipping. According to various industry studies, companies report seeing around a 20-25% drop in damaged products after switching to Euro pallets instead of older models. Less damaged merchandise means better overall efficiency throughout the supply chain, plus happier customers who get what they ordered without any issues. When fewer items arrive broken or damaged, businesses save money on returns and repairs, not to mention building trust with clients who come to expect reliable delivery every time.

Sustainability Advantages of Euro Pallet Systems

Circular Economy Impact: Reuse and Recycling Metrics

Euro pallets play a big role in what we call the circular economy, helping companies keep things going longer instead of just tossing them out after one use. Compared to those throwaway boxes and containers, Euro pallets let businesses run their logistics operations in a greener way since they get used over and over again before finally getting recycled. Industry folks say most Euro pallets last around 20 trips through warehouses and distribution centers, which means fewer trees need chopping down for fresh wood products. Some research into green materials showed that companies switching to these reusable options save roughly 30% on packaging expenses and slash material consumption by half or more. When looking at the bigger picture, the difference between Euro pallets and regular disposable ones is pretty huge from an environmental standpoint. According to findings published somewhere called the Journal of Sustainable Materials, making the switch cuts down on waste piles, makes day-to-day operations smoother, and leaves a smaller mark on our planet's climate overall.

CO2 Reduction Success Stories (Barilla Case Study)

Looking at what happened with Barilla shows just how much difference Euro pallets can make when it comes to cutting down on CO2 emissions. When Barilla started using these pallets throughout their supply chain operations, they managed to slash their carbon output by around 12%. One of the key things they found was that because Euro pallets carry loads so efficiently, fuel consumption dropped about 8% overall. This happens mostly because the way goods get packaged and transported becomes much better organized. Logistics consultant Dr. Paul Martinez has pointed out several times now that switching to Euro pallets isn't just good business sense but also makes environmental sense since it cuts down on the carbon footprint quite noticeably. According to figures shared by the European Pallet Association, businesses that have made the switch generally see lower emissions levels while also getting improvements in how resilient and efficient their entire supply chains become.

Implementing Euro Pallets: Practical Strategies

Compliance with EU Pallet Pooling Standards (EPAL)

For companies working with Euro pallets in global trade and logistics, following EPAL standards isn't just important it's absolutely necessary. These regulations set quality benchmarks that keep pallets performing well over time while supporting safer handling and reducing waste across supply chains. To stay compliant, businesses need to handle several key tasks regularly inspecting and repairing damaged pallets, getting materials only from approved suppliers, and sticking to standard manufacturing practices throughout production. Many organizations struggle with compliance because regulations keep changing and documentation requirements get complicated fast. Some find success by implementing good tracking systems for their compliance status and making sure employees understand the rules through ongoing education programs rather than one-time training sessions.

Cost-Benefit Analysis for Long-Term Adoption

Switching over to Euro pallets does come with some upfront costs for buying them, keeping them in good shape, and running operations around them. Still, most find that what they gain makes those initial investments worth it. When looking at the numbers, companies should consider both the obvious wins like fewer damaged goods and smoother logistics flow, plus the less measurable perks such as looking better on sustainability reports. Take food distributors for instance many report cutting down waste and saving money once they made the switch. Some warehouses even saw their turnaround times drop by nearly 30%. While no one claims it's always easy, those who stick with it tend to see real improvements down the road. The key is not just crunching the numbers but understanding how these changes actually play out day to day across different parts of the supply chain network.

Euro Pallets in Global Trade Operations

Cross-Border Compatibility: EU to Global Markets

Euro pallets really help with moving stuff between countries, especially within the EU and around the world. When everyone agrees on standard sizes and maintains good quality, shipping gets much easier. Less time wasted repacking items just because different places want different things. The fact that so many countries accept Euro pallets matters a lot for companies exporting products. It cuts down on waiting times and those frustrating logistical headaches when getting goods from point A to B. Big names like DHL and IKEA have seen real improvements in their export work thanks to these standardized pallets. They simply don't face as many problems during transport anymore, which saves money and keeps customers happy.

Digital Integration with RFID Tracking Systems

When RFID tracking gets integrated with standard Euro pallets, it represents a game changer for warehouse managers everywhere. The tech gives companies live updates on where their stock actually is, which cuts down errors in inventory counts and speeds up day-to-day operations significantly. With RFID tags attached, businesses can track exactly when pallets move from one location to another and pinpoint products throughout the facility, making it easier to spot issues before they become major problems. Better sight into what's happening with shipments means fewer misplaced items and less risk of theft or damage during transit. Retailers, manufacturers, and distributors in industries ranging from automotive parts to pharmaceuticals are already adopting this approach to get clearer pictures of their supply chains. The result? Faster response times to customer orders and improved satisfaction rates across international markets.

Initial Investment vs Lifetime Value Calculations

Businesses thinking about switching to Euro pallets usually run into some pretty big upfront costs first off. They need money for buying new equipment and training staff on proper handling techniques. But looking past those initial expenses reveals some real advantages over time. Most companies calculate their return by factoring in things such as less product damage during transport, cheaper repairs since Euro pallets last longer, and better flow through warehouses and distribution centers. Investing in these tough, reusable pallets helps meet green targets too while making supply chains work smoother day to day. Take LPR for example they saw their bottom line improve after replacing old wooden pallets with Euro ones across multiple facilities. Their warehouse manager mentioned something interesting though there was definitely a learning curve at first but once everyone got used to them, productivity jumped quite a bit compared to what they had before.

Transitioning from Disposable to Reusable Systems

Moving away from single-use Euro pallets toward reusable ones presents real challenges for many companies. Some common roadblocks include pushback from employees used to old methods, the need for fresh training sessions, plus those initial investment costs that make managers hesitant. Getting through these obstacles requires careful planning though. Start talking to everyone involved right at the beginning stages, roll out proper training so nobody gets left behind, and keep pointing out how much money can be saved down the line while also helping protect the environment. Take Euro Pool Group for instance they actually made the switch work by setting up their own pallet sharing network which cut waste and fixed problems caused by constantly buying new boxes. Their experience shows what's possible when companies commit to greener practices not just for show but because it makes good business sense too. Ultimately making this change helps build better supply chains and keeps operations in step with today's green expectations without breaking the bank.

Future-Proofing with Euro Pallet Innovations

Smart Pallet Technologies in Industry 4.0

Smart pallet tech is changing how supply chains operate in the Industry 4.0 era through IoT integration right into standard Euro pallets. With these smart features, companies can track where their pallets are at any given moment, check if they're damaged during transport, and even know what kind of cargo they carry. The shift toward technologically enhanced Euro pallets means warehouses and distribution centers see fewer misplaced goods, less product damage, and much better stock control across their operations. Major players such as CHEP have already rolled out RFID chips on millions of pallets while Loscam is testing temperature sensors that alert logistics managers when perishables get too warm during transit. Looking ahead, expect to see even more innovations in pallet technology as manufacturers work to keep pace with digital transformation demands throughout global supply networks.

Automated Handling Systems Compatibility

Euro pallets fit right into automated handling systems which boosts how much stuff gets moved around in warehouses. The fact that they come in standard sizes and are built tough makes them perfect partners for robots and those fancy storage systems we see popping up everywhere lately. Warehouses using these pallets report better efficiency rates and fewer accidents because workers aren't lifting as much heavy stuff manually all day long. Take a look at big names like Amazon and Walmart for instance. Both companies rolled out automated systems with Euro pallets across multiple distribution centers last year. What did this do? Well, it cut down on labor costs significantly while making their supply chains greener since there's less need for disposable packaging materials now that everything fits neatly onto those standardized pallets.

FAQs About Euro Pallets

What are the dimensions of a Euro pallet?

Euro pallets have standardized dimensions of 1200 x 800 mm, which facilitate seamless logistics operations globally.

Why are Euro pallets more durable than traditional pallets?

Euro pallets are constructed from high-quality wood, allowing them to withstand heavier loads and reducing the chances of damage, increasing their lifespan compared to traditional options.

How do Euro pallets contribute to sustainability?

They support the circular economy by enabling reuse and recycling, reducing raw material demand and packaging costs, and cutting down on carbon footprints.

What is the importance of EPAL compliance for Euro pallets?

EPAL standards ensure that Euro pallets meet high-quality specifications for efficient, safe, and sustainable logistics operations, which is critical for international trade.

How does RFID tracking integration benefit Euro pallet usage?

RFID tracking provides real-time tracking capabilities, improving inventory management accuracy and operational efficiency by offering insights into pallet movement and product location.

Table of Contents

- The Role of Euro Pallets in Modern Supply Chains

- Key Benefits of Euro Pallets for Logistics Optimization

- Sustainability Advantages of Euro Pallet Systems

- Implementing Euro Pallets: Practical Strategies

- Euro Pallets in Global Trade Operations

- Future-Proofing with Euro Pallet Innovations

- FAQs About Euro Pallets