The Environmental Impact of Plastic Pallets

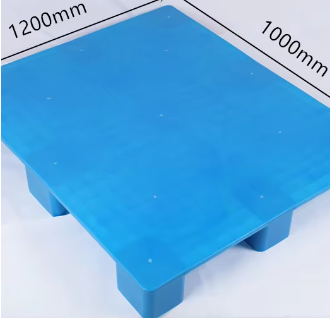

Introduction to Plastic Pallets

Plastic Pallets have become increasingly common in global logistics and supply chain operations. Once dominated almost exclusively by wooden pallets, the industry has seen a steady shift toward plastic alternatives in warehouses, factories, and transport systems. The reasons for this shift are clear: plastic versions are lightweight, resistant to moisture, durable, and hygienic, making them suitable for industries ranging from food and beverage to pharmaceuticals. However, as with any industrial material, their environmental impact must be critically examined. The widespread adoption of Plastic Pallets raises questions about sustainability, recyclability, energy use, and overall ecological footprint.

The Life Cycle of Plastic Pallets

Raw Materials and Production

Plastic Pallets are typically made from high-density polyethylene (HDPE) or polypropylene (PP). Both are petroleum-based polymers, meaning that their production begins with the extraction of fossil fuels. The refining and polymerization processes consume large amounts of energy and generate greenhouse gas emissions. Compared to wooden pallets, which can be sourced from renewable timber, the initial carbon footprint of producing plastic is relatively high.

Usage Phase

The advantage of Plastic Pallets lies in their durability. A wooden pallet may last for a few trips before requiring repair or replacement, while a plastic version can last up to 10 years or more depending on usage. This long service life helps offset the high initial carbon footprint by spreading it over many more trips. Additionally, plastic is resistant to moisture, pests, and chemicals, making it suitable for sensitive industries that require strict hygiene standards.

End-of-Life Disposal

At the end of their service life, Plastic Pallets present both opportunities and challenges. On the positive side, many can be recycled into new pallets or other plastic products. Closed-loop recycling systems exist where old pallets are collected, shredded, and remanufactured. However, if not properly recycled, these pallets contribute to plastic waste in landfills or the environment, where they can persist for hundreds of years.

Environmental Advantages of Plastic Pallets

Durability and Longevity

One of the most important environmental benefits of Plastic Pallets is their durability. Because they last longer than wood, fewer replacements are required, reducing the demand for raw materials and minimizing waste generation. In logistics systems where pallets are reused frequently, the durability advantage is significant.

Recyclability

Plastic Pallets can be recycled multiple times, provided they are collected and processed appropriately. Unlike many single-use plastic products, pallets are often part of structured supply chain systems, which makes collection for recycling more practical. Recycling reduces reliance on virgin plastic, lowering energy use and emissions in the long term.

Hygienic Properties

Plastic Pallets are easy to clean and disinfect. In industries like food, healthcare, and pharmaceuticals, this reduces the risk of contamination. By maintaining hygiene standards, Plastic Pallets prevent product losses due to spoilage or contamination, indirectly reducing waste across the supply chain.

Reduced Use of Chemicals

Wooden pallets are often treated with chemicals to resist pests, mold, or moisture. These chemicals can have environmental consequences when pallets are discarded or burned. Plastic alternatives avoid the need for such treatments, minimizing chemical pollution.

Environmental Disadvantages of Plastic Pallets

Fossil Fuel Dependence

Because they are made from petroleum-based polymers, Plastic Pallets depend heavily on nonrenewable resources. This dependence contributes to greenhouse gas emissions from extraction to production, making the early stages of their life cycle environmentally intensive.

High Energy Production Costs

The manufacturing process for Plastic Pallets consumes significant amounts of energy. From refining crude oil to molding finished pallets, the energy intensity is considerably higher than that of wooden pallets.

End-of-Life Challenges

While recycling is possible, it is not always guaranteed. In regions lacking recycling infrastructure, Plastic Pallets can end up in landfills. There they degrade extremely slowly, posing long-term environmental risks. Mismanaged disposal can also contribute to the growing problem of plastic pollution.

Transportation and Carbon Footprint

Although lighter than wood, some Plastic Pallets, especially those designed for heavy loads, can be heavier due to their dense construction. This can increase fuel consumption in transportation compared to lightweight wooden pallets, particularly in industries prioritizing low-cost shipping.

Comparing Plastic Pallets and Wooden Pallets

Carbon Footprint

Wooden pallets generally have a lower initial carbon footprint because they are made from renewable resources. However, their shorter lifespan means more frequent replacements and repairs. Plastic Pallets have a higher initial footprint but may perform better over time due to their longevity.

Resource Sustainability

Wood is renewable if sourced from sustainably managed forests, while plastic depends on finite fossil fuels. This makes wooden pallets inherently more sustainable from a raw material perspective. However, if Plastic Pallets are recycled efficiently, they can achieve a comparable sustainability profile.

Waste Generation

Wooden pallets produce organic waste that decomposes naturally, while plastic waste persists. However, broken wooden pallets are often discarded after a short time, while damaged Plastic Pallets can be recycled or reprocessed.

Industry Suitability

Plastic Pallets excel in industries where hygiene and durability are critical. Wooden pallets are better suited for short-term use and where environmental regulations discourage plastic use. The choice between them depends on balancing operational needs with sustainability goals.

Innovations in Sustainable Plastic Pallets

Use of Recycled Plastics

Some manufacturers now produce Plastic Pallets from recycled HDPE or PP, reducing the need for virgin fossil-based inputs. This approach lowers the carbon footprint and encourages circular economy practices.

Bioplastics and Alternatives

Emerging technologies are experimenting with bioplastics made from renewable resources such as corn starch, sugarcane, or agricultural waste. Although not yet widespread, bioplastic pallets could offer the durability of plastic with lower environmental impact.

Take-Back and Closed-Loop Programs

Many pallet manufacturers and logistics providers now operate take-back programs, where old pallets are collected and reprocessed into new ones. This minimizes waste and ensures materials remain within the supply chain loop rather than being discarded.

Lightweight Design Innovations

New designs focus on reducing material use without sacrificing strength. By optimizing structural integrity, manufacturers can produce lighter Plastic Pallets that reduce transportation emissions.

Conclusion

Plastic Pallets present a complex environmental profile. On one hand, they are durable, reusable, and recyclable, making them a more sustainable choice in controlled logistics systems compared to disposable wooden pallets. On the other hand, they rely on fossil fuels, consume significant energy during production, and pose end-of-life challenges if not properly recycled. The balance between advantages and disadvantages largely depends on how they are managed throughout their life cycle. In industries with robust recycling systems and high reuse rates, Plastic Pallets can significantly reduce environmental impact. However, in regions with poor waste management, they risk contributing to the global plastic pollution crisis. For businesses, the choice between plastic and wood should consider operational needs, environmental regulations, and long-term sustainability goals.

FAQ

Are Plastic Pallets environmentally friendly?

They can be, depending on how they are manufactured, used, and recycled. Their long lifespan and recyclability make them environmentally advantageous in well-managed systems.

What are Plastic Pallets made from?

They are typically made from high-density polyethylene (HDPE) or polypropylene (PP), both derived from petroleum.

How long do Plastic Pallets last?

They can last up to 10 years or more depending on usage, significantly longer than most wooden pallets.

Can Plastic Pallets be recycled?

Yes, many can be recycled into new pallets or other products, but recycling depends on available infrastructure.

Do Plastic Pallets reduce waste?

Yes, their durability reduces the need for frequent replacements, which minimizes waste compared to wood.

Are Plastic Pallets better than wood?

It depends on context. They are better in industries needing hygiene and durability, but wood may be more sustainable where renewable forestry practices exist.

Do Plastic Pallets contribute to plastic pollution?

They can, if not properly recycled. Mismanaged disposal leads to long-lasting waste in landfills and ecosystems.

Are there eco-friendly alternatives to Plastic Pallets?

Yes, some pallets are made from recycled plastics or bioplastics, and manufacturers are exploring sustainable innovations.

Do Plastic Pallets use less energy in transport?

Often yes, because many designs are lighter than wood, but heavy-duty versions can sometimes outweigh wood.

How can businesses minimize the environmental impact of Plastic Pallets?

By using recycled materials, participating in closed-loop programs, and ensuring proper recycling at end-of-life.

Table of Contents

- The Environmental Impact of Plastic Pallets

- Introduction to Plastic Pallets

- The Life Cycle of Plastic Pallets

- Environmental Advantages of Plastic Pallets

- Environmental Disadvantages of Plastic Pallets

- Comparing Plastic Pallets and Wooden Pallets

- Innovations in Sustainable Plastic Pallets

- Conclusion

-

FAQ

- Are Plastic Pallets environmentally friendly?

- What are Plastic Pallets made from?

- How long do Plastic Pallets last?

- Can Plastic Pallets be recycled?

- Do Plastic Pallets reduce waste?

- Are Plastic Pallets better than wood?

- Do Plastic Pallets contribute to plastic pollution?

- Are there eco-friendly alternatives to Plastic Pallets?

- Do Plastic Pallets use less energy in transport?

- How can businesses minimize the environmental impact of Plastic Pallets?