המרת יעילות בשרשרת האספקה עם פתרונות מתקדמים לטיפול בחומרים

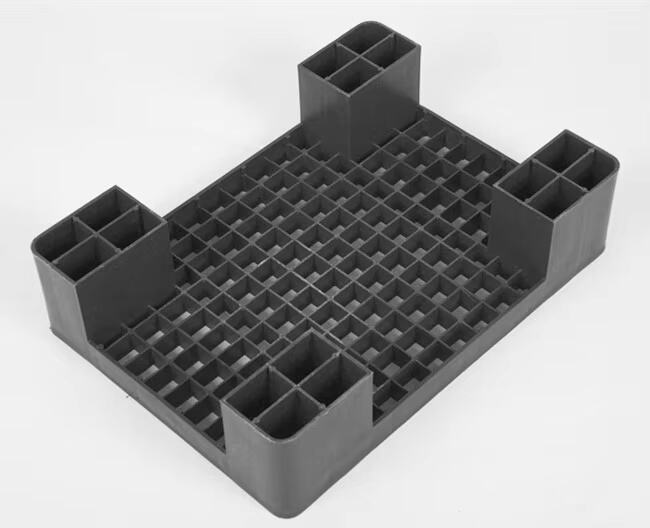

תעשיית הלוגיסטיקה חווה מעבר מהפכני באיך שמספקים, מטפלים ובמוצרי סחורה ברחבי שרשרות אספקה גלובליות. בפרצוף של המהפך הזה נמצאת האימוץ ההולך וגובר של מטענים פלסטיים , שמחליפים במהרה את החלופות העץ המסורתיות במפעלי אחסון ומוקדי הפצה ברחבי העולם. פתרונות הטיפול בחומרים החדישים הללו הוכחו כמשנים-משחק בפעולות לוגיסטיקה מודרניות, ומציעים יתרונות רבים שמשפיעים ישירות על יעילות תפעולית ותוצאות כספיות.

ככל ששרשראות האספקה הופכות מורכבות יותר ודרישות ליציבות מגדלות, עסקים מגלים את היתרונות החשובים שמשטחים פלסטיים מביאים לתפעול שלהם. מהעומס המשופר לתקני ההיגיינה המוגברים, פתרונות אלו לטיפול בחומרים מודרניים משנים את הדרך בה חברות מתקרבות לתהליכי הלוגיסטיקה שלהן. בואו נחקור את הסיבות המכריעות שבגינן יותר ארגונים עוברים למשטחי פלסטיק וכיצד בחירה זו משפיעה על עתיד הלוגיסטיקה.

תועלת סביבתית וקיימאbilité

הקטנת השפעה סביבתית באמצעות חזרה לשימוש

אחת היתרונות המשמעותיים ביותר של משאות פלסטיק היא היכולת להיבדק מבחינה סביבתית. בניגוד למשאות עץ שغالבהן נשלחות לאשפה לאחר תום תקופת השימוש, משאות פלסטיק ניתנות לשימוש חוזר באופן מלא וניתן להמירן למשאות חדשות או למוצרים פלסטיים אחרים. מערכת מחזור סגורה זו מפחיתה בצורה משמעותית את כמות הפסולת ותומכת ביוזמות קיימות של חברות. כאשר משאת פלסטיק מגיעה לסוף מחזור החיים שלה, ניתן לפרק אותה ולבנות מחדש למוצרים חדשים, מה שיוצר גישה כלכלית מעגלית באמת להתמודדות עם חומרים.

תהליכי הייצור המודרניים של משאות פלסטיק כוללים גם חומרים מחזוריים, ובכך מפחיתים עוד יותר את ההשפעה הסביבתית של ייצורם. מחויבות זו לקיימות מדברת אל הלב של צרכנים דואגים לסביבה ועוזרת לחברות לעמוד ביעדי האחריות החברתית העסקיית שלהן.

אורך חיים ממושך וצריכת משאבים מופחתת

העמידות של משטחים מפלסטיק מתורגמת ישירות להטבות סביבתיות בזכות אורך החיים הארוך שלהם. בעוד שמשטחים מעץ דורשים לרוב החלפה לאחר 15-20 נסיעות, משטח פלסטיק בשימוש תקין יכול לשמש 100 פעמים או יותר. עמידות זו משמעותה שנצרكات פחות חומרים לייצור משטחים חדשים, מה שמוביל לרגלי פootprint סביבתי נמוך יותר לאורך זמן.

יתרה מכך, משטחים מפלסטיק אינם זקוקים לטיפול באמצעות כימיקלים או חומרי הדברה מזיקים, שغالבים נדרשים במשטחים מעץ כדי למנוע הזנחה ותהליך ריקבון. הסרת הטיפול הכימי אינה רק הופכת את המשטחים מפלסטיק לבטוחים יותר בהובלה, אלא גם מונעת את שחרור חומרים שעלולים להיות מזיקים לסביבה.

העלאה של יעילותperation

מהירות טיפול משופרת בחומרים

הממדים המוסכמים והמשטחים החלקים של משאות פלסטיק תורמים בצורה משמעותית להפעלת חומרים מהירה יותר. הבנייה האחידה שלהם מבטיחה ביצועים אמינים במערכות אוטומטיות, ומצמצמת את הסיכון לפקקים והאטות שיכולים להתרחש עם משאות עץ. גם המאסה הקלילה של משאות פלסטיק מאפשרת טיפול ידני מהיר יותר, מקטינה את עייפות המשغل ומשפרת את היעילות במקום העבודה.

בתפעול נפח גבוה, הרווחים בכفاءה יכולים להתבטא בחיסכון משמעותי בזמן. עובדים יכולים להזיז יותר محمול בשעה, והמערכות האוטומטיות יכולות לפעול במהירויות אופטימליות ללא צורך בהתאמות תכופות או עצירות תחזוקה עקב בעיות הקשורות למשאות.

צורך מינימלי בzechyout ציוד

הבנייה החלקה של משטחים פלסטיים, ללא קיסמים, ממזערת את ההתבלה והנזק לציוד טיפול בחומרים. בניגוד למשטחים עציים שיכולים לשחרר שברי עץ ולגרום נזק למערכות הסילסולים ולחצי ציוד היעילה, המשטחים הפלסטיים שומרים על שלמותם לאורך מחזור החיים שלהם. זה גורם לצרכים מופחתים בטיפול ובתקופת חיים ארוכה יותר של הציוד, מה שמוביל לחסכונות משמעותיים עם הזמן.

יתרה מכך, המשקל והממדים המוסכמים של המשטחים הפלסטיים מאפשרים תכנון מטענים מדויק יותר ושימוש טוב יותר במרחב האחסון. חיזוי זה בתכונות הטיפול עוזר לאפשר אופטימיזציה של פעולות המחסן ומפחית את הסיכון לנזק בציוד עקב מטענים לא סדירים.

יעילות עלות ותגמול על ההשקעה

יתרונות עלות לטווח ארוך

בעוד ההשקעה הראשונית במשטחים מפלסטיק עשויה להיות גבוהה יותר מאלטרנטיבות מעץ, עלות המחייה הכוללת נוטה להיות משתלמת יותר לאורך זמן. אורך החיים הממושך של משטחים מפלסטיק גורם לצריכה פחותה של רכישות תמורה, ועמידותם מובילה להפחתת נזקי מוצרים במהלך הובלה. גורמים אלו תורמים לחיסכון משמעותי בעלויות לטווח הארוך עבור עסקים שמממשים פתרונות של משטחים מפלסטיק.

המשקל הקל של המשטחים מפלסטיק תורם גם להפחתת עלויות הובלה. עם עליית מחירי הדלק, חיסכון במשקל הנגרם מהשימוש במשטחים מפלסטיק במקום במשטחים מעץ יכול להוביל לצמצום משמעותי בהוצאות שילוח, במיוחד עבור פעולות בעלות נפח גבוה.

הפחתת נזקי מוצרים ותביעות ביטוח

המשטח החלק וה אחיד של משאות פלסטיק עוזר להגן על סחורות במהלך אחסון ותעבורה. בניגוד למשאות עץ שעשויות להכיל מסמרים בולטים או קוצים, למשאות פלסטיק יש סיכון מינימלי לגרום נזק למוצרים או לעטיפות. הגנה זו תורמת לפחת טענות ביטוח ולחיסכון בעלויות הקשורות לסחורה פגומה.

בנוסף, המבנה היציב של משטחי פלסטיק מבטיח ערימה ואחסון אמינים יותר, ומפחית את הסיכון לקריסה או תזוזת המטען במהלך ההובלה. יציבות משופרת זו תורמת לאבטחת מטען טובה יותר ולפחות מקרים של נזק למוצר במהלך הטיפול והמשלוח.

יתרונות היגיינה ובטיחות

היערכות טובה יותר לדרישות בטיחות המזון

בתעשיית המזון והתרופות, משטחי פלסטיק מציעים מאפיינים היגייניים מובילים בהשוואה לחלופות עץ. המשטח שאינו חודר מניע ספיגת נוזלים וחומרים כימיים, מה שמאפשר ניקוי וסניטציה קלה יותר. תכונה זו קריטית במיוחד לצורך שמירה על התאמה להוראות הבטיחות המחמירות של מזון ולתרגולים טובים של ייצור.

היכולת לנקות ולסנן משטחים פלסטיים בצורה מעמיקה גם כן הופכת אותם לאידיאליים לסביבות חדר נקי ויישומים רגישים אחרים בהם שליטה בתוספת היא חיונית. עמידותם בגדילה של בקטריות והמשטחים הקלי ניקוי שלהם עוזרים לשמור על הסטנדרטים הגבוהים ביותר של היגיינה לאורך כל שרשרת האספקה.

בטיחות משופרת במקום העבודה

המשקל המתון והבנייה החלקה של משטחי פלסטיק תורמים לשיפור הבטיחות במקום העבודה. עובדים פחות סביר שיפגעו מרסיסים או מסמרות בולטות, והמשקל הקל יותר מפחית את הסיכון לפציעות מתיחה במהלך טיפול ידני. היתרונות הללו יכולים להוביל לצמצום תאונות במקום העבודה ולפחת דמי ביטוח.

יתרה מכך, משטחי פלסטיק משליכים את הסיכון מאבקת עץ, אשר עלולה להוות סיכון נשימתי בסביבות מחסן. התכונות האש כבויות שלהם גם מחזקות את הבטיחות מפני אש, מה שהופך אותם לבחירה מועדפת במתקנים שבהם ניהול סיכון מאש הוא עדיפות.

שאלות נפוצות

מהי תוחלת החיים הטיפוסית של משטחי פלסטיק בהשוואה למשטחי עץ?

משטחי פלסטיק נוטים לשרוד 5-10 פעמים יותר מאשר משטחי עץ, עם תוחלת חיים ממוצעת של למעלה מ-100 טרנזקציות בהשוואה ל-15-20 עבור משטחי עץ. עמידות מוגדלת זו הופכת אותם לבחירה כדאית מבחינה כלכלית לשימוש ארוך טווח בפעולות שרשרת האספקה.

האם שווייה השקעה ראשונית גבוהה יותר במשטחים מפלסטיק?

כן, למשטחים מפלסטיק יש בדרך כלל תשואה גבוהה על ההשקעה הודות להפחתת עלויות תמורה, עלויות תחבורה נמוכות יותר, הפחתת נזקי מוצרים ויעילות تشغילית משופרת. עלות המלכורה הכוללת לאורך זמן החיים שלהם נמוכה באופן משמעותי בהשוואה לחלופות עץ.

האם משטחים מפלסטיק יכולים לשאת את אותה כמות משקל כמו משטחים מעץ?

משטחים מודרניים מפלסטיק מעוצבים כך שיוכלו לעמוד בעומס שווה או גדול יותר מזה של משטחים מעץ. משטחים איכותיים מפלסטיק יכולים לשאת עומס דינמי של עד 5,000 פאונד ועומס סטטי של עד 30,000 פאונד, מה שהופך אותם למתאימים לרוב היישומים התעשייתיים.

באילו תעשיות נהנים הכי הרבה מהשימוש במשטחים מפלסטיק?

תעשיות עם דרישות היגיינה חמורות, כגון מזון ומשקאות, תרופות ואלקטרוניקה, נהנות בצורה משמעותית ממטענים מפלסטיק. בנוסף, מחסני אוטומציה, עסקים שמתמקדים ביצוא, וחברות שמתרכזות בהישרפה, מוצאים את המטענים מפלסטיק מועילים במיוחד להפעלתן.