How Plastic Pallets Can Improve Warehouse Efficiency

Introduction to Plastic Pallets in Warehousing

In the modern supply chain, efficiency is the cornerstone of competitiveness. Warehouses play a central role in ensuring goods are moved, stored, and distributed effectively. Within this system, pallets serve as the foundation of material handling, enabling goods to be stacked, stored, and transported seamlessly. Traditionally, wooden pallets dominated the industry, but recent years have seen a strong shift toward Plastic Pallets. Their durability, uniformity, hygiene, and compatibility with automation make them a superior choice for businesses aiming to optimize warehouse operations. By examining their specific advantages, it becomes clear how Plastic Pallets can transform logistics and deliver measurable improvements in efficiency.

Durability and Longevity of Plastic Pallets

Resistance to Wear and Tear

Plastic Pallets are designed to withstand heavy loads and frequent handling. Unlike wooden pallets, which splinter, crack, or degrade after repeated use, plastic versions maintain structural integrity for many years. This durability reduces downtime caused by broken pallets and minimizes the risk of product damage.

Cost Efficiency Over Time

Although the upfront cost of Plastic Pallets is higher than wooden alternatives, their long lifespan makes them more cost-efficient. A plastic pallet can last up to ten times longer than wood, which means fewer replacements, less waste, and lower long-term expenses for warehouses.

Weather and Moisture Resistance

Plastic does not absorb moisture, making these pallets resistant to rot, mold, and warping. This advantage ensures consistent performance in warehouses with varying temperature and humidity conditions, and it eliminates costly product damage caused by water exposure.

Standardization and Uniformity

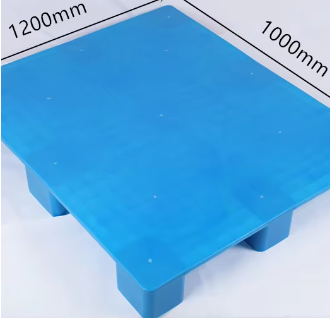

Consistent Dimensions

Plastic Pallets are manufactured with high precision, ensuring uniform size and weight across all units. This consistency improves stacking stability, enhances safety, and makes warehouse planning more predictable. Automated storage and retrieval systems, conveyors, and forklifts operate more efficiently when handling uniform pallets.

Compatibility with Automation

As warehouses adopt robotics and automated systems, the uniformity of Plastic Pallets becomes increasingly valuable. Automation requires consistent pallet dimensions to avoid errors or malfunctions. Wooden pallets, with their irregularities, often disrupt automated workflows, while plastic versions integrate smoothly into mechanized systems.

Improved Load Stability

Consistent sizing ensures that loads are evenly distributed, reducing the risk of shifting or collapsing stacks. This enhances warehouse safety and reduces losses from damaged goods.

Hygiene and Safety Advantages

Easy Cleaning

Plastic Pallets are non-porous and easy to clean, making them ideal for industries requiring high hygiene standards, such as food, pharmaceuticals, and healthcare. They can be washed, disinfected, and dried quickly, ensuring compliance with regulations like FDA and EU standards.

Reduction in Contamination Risks

Unlike wood, plastic does not harbor insects, bacteria, or fungi. This reduces contamination risks in warehouses where hygiene is critical and lowers the need for fumigation or chemical treatments.

Improved Worker Safety

Plastic Pallets are lighter and free of sharp edges, nails, or splinters that can injure workers. Safer equipment translates to fewer workplace accidents, reduced liability, and smoother operations.

Space Optimization and Handling Efficiency

Nestable and Stackable Designs

Many Plastic Pallets feature nestable or stackable designs that save space when pallets are not in use. Nestable pallets can be stacked inside one another, reducing the amount of storage space required in a warehouse. This optimization translates into cost savings on warehouse space and transport.

Lightweight Yet Strong

Plastic Pallets are generally lighter than wood, which reduces the physical strain on workers and lowers transportation costs. Despite being lightweight, they are engineered to handle heavy loads, striking an ideal balance between efficiency and strength.

Consistency in Racking Systems

The structural integrity of Plastic Pallets ensures they work reliably with racking systems. Unlike warped wooden pallets, which can cause instability, plastic versions fit securely in racks, improving warehouse organization and safety.

Contribution to Supply Chain Efficiency

Faster Handling

Uniform and durable pallets allow forklifts and pallet jacks to handle goods more quickly and with fewer adjustments. This speeds up loading, unloading, and internal movements, contributing to shorter turnaround times in busy warehouses.

Reduced Downtime

With fewer pallet failures, warehouses experience less downtime caused by damaged goods or broken pallets that disrupt workflows. Consistency in pallet performance improves reliability throughout the supply chain.

Enhanced Traceability

Some Plastic Pallets can be embedded with RFID tags or barcodes, enabling real-time tracking of goods. This supports advanced inventory management systems, reduces losses, and increases transparency across the supply chain.

Sustainability Considerations

Longer Service Life

The extended lifespan of Plastic Pallets reduces the number of replacements, conserving resources and minimizing waste generation compared to frequently replaced wooden pallets.

Recyclability

At the end of their service life, Plastic Pallets can be collected and recycled into new pallets or other plastic products. Closed-loop recycling programs make them part of a circular economy model, lowering overall environmental impact.

Reduced Resource Use in the Long Term

Although the production of Plastic Pallets is more resource-intensive initially, their longevity and recyclability balance the environmental equation over time, particularly when integrated into sustainable warehouse practices.

Industry Applications

Food and Beverage

Plastic Pallets are widely used in food supply chains due to their hygienic properties. They prevent contamination, comply with international food safety standards, and allow easy cleaning, making them the preferred choice for perishable goods.

Pharmaceuticals and Healthcare

In industries where sterility and safety are paramount, Plastic Pallets ensure compliance with strict regulations. Their resistance to contamination and ease of cleaning make them essential for transporting medicines and medical equipment.

Automotive and Heavy Industry

Durable and strong, Plastic Pallets are also used in the automotive sector for transporting heavy parts. Their ability to withstand high loads without breaking supports efficiency in manufacturing supply chains.

Retail and E-Commerce

Retail warehouses benefit from the uniformity and durability of Plastic Pallets. Their integration with automated systems and suitability for quick turnover logistics align with the fast-paced demands of e-commerce.

Challenges and Limitations

Higher Initial Cost

The most common concern with Plastic Pallets is their higher upfront cost compared to wooden pallets. This can be a barrier for smaller warehouses or those with limited budgets. However, the long-term benefits often outweigh the initial investment.

Recycling Infrastructure

While recyclable, Plastic Pallets depend on proper recycling infrastructure. In regions without such systems, end-of-life pallets may still contribute to waste issues.

Suitability for One-Way Shipments

For one-way exports, wooden pallets may still be preferable due to lower cost and easier disposal. Plastic Pallets are best suited for closed-loop systems where they can be reused multiple times.

Conclusion

Plastic Pallets have emerged as a transformative solution for improving warehouse efficiency. Their durability, uniformity, hygiene, and compatibility with automation make them superior to traditional wooden pallets in many applications. They reduce downtime, enhance safety, optimize space, and support sustainability goals through recyclability and long service life. While the initial investment is higher, the return on efficiency, cost savings, and environmental benefits make Plastic Pallets a strategic choice for modern warehouses. As global supply chains become more complex and competitive, adopting Plastic Pallets is no longer just an operational upgrade but a necessity for long-term efficiency and resilience.

FAQ

Why are Plastic Pallets more durable than wood?

They are resistant to splintering, warping, and moisture damage, allowing them to last up to ten times longer than wooden pallets.

How do Plastic Pallets improve warehouse safety?

They reduce the risk of injuries since they are lighter and free of nails or splinters, making them safer for workers to handle.

Are Plastic Pallets suitable for automated systems?

Yes, their uniform dimensions make them highly compatible with automation, including conveyors and robotic systems.

Do Plastic Pallets save space in warehouses?

Yes, many are designed to be nestable or stackable, reducing the storage space required when not in use.

Are Plastic Pallets recyclable?

Yes, they can be collected and recycled into new pallets or other products, contributing to a circular economy.

What industries benefit most from Plastic Pallets?

Food, pharmaceuticals, automotive, and retail industries benefit significantly due to hygiene, strength, and uniformity requirements.

Are Plastic Pallets more expensive than wooden ones?

Initially, yes, but their longer lifespan and reduced maintenance make them more cost-effective over time.

Can Plastic Pallets handle heavy loads?

Yes, they are engineered to carry heavy loads and are often used in industries that require robust performance.

Do Plastic Pallets reduce downtime?

Yes, their durability and reliability reduce pallet failures, ensuring smoother warehouse operations and fewer disruptions.

Are Plastic Pallets environmentally friendly?

When used in closed-loop systems and recycled properly, they offer significant sustainability advantages compared to disposable wooden pallets.

Table of Contents

- How Plastic Pallets Can Improve Warehouse Efficiency

- Introduction to Plastic Pallets in Warehousing

- Durability and Longevity of Plastic Pallets

- Standardization and Uniformity

- Hygiene and Safety Advantages

- Space Optimization and Handling Efficiency

- Contribution to Supply Chain Efficiency

- Sustainability Considerations

- Industry Applications

- Challenges and Limitations

- Conclusion

-

FAQ

- Why are Plastic Pallets more durable than wood?

- How do Plastic Pallets improve warehouse safety?

- Are Plastic Pallets suitable for automated systems?

- Do Plastic Pallets save space in warehouses?

- Are Plastic Pallets recyclable?

- What industries benefit most from Plastic Pallets?

- Are Plastic Pallets more expensive than wooden ones?

- Can Plastic Pallets handle heavy loads?

- Do Plastic Pallets reduce downtime?

- Are Plastic Pallets environmentally friendly?