The Advantages of Using Plastic Pallets in Logistics

Introduction to Plastic Pallets in Modern Logistics

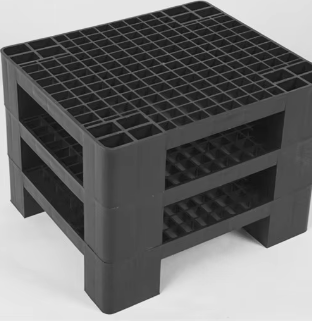

In the fast-paced world of global logistics, efficiency, durability, and sustainability are critical factors. Pallets form the backbone of material handling systems, enabling the movement, storage, and transport of goods across warehouses, distribution centers, and international shipping routes. While wooden pallets have traditionally dominated the industry, Plastic Pallets are increasingly being adopted by businesses around the world. They offer durability, hygiene, uniformity, and compatibility with automation, making them a superior choice for many industries. As supply chains become more complex and demand for sustainable solutions grows, understanding the advantages of Plastic Pallets becomes essential for businesses looking to remain competitive.

Durability and Longevity

Resistance to Damage

One of the most significant advantages of Plastic Pallets is their durability. Wooden pallets often splinter, warp, or crack after repeated use, while plastic versions maintain structural integrity over many years. They resist impact, heavy loads, and rough handling in ways that wood cannot. This makes them a reliable option for industries requiring consistent performance.

Cost Savings Over Time

Although Plastic Pallets come with a higher initial purchase price, their long lifespan translates into lower costs over time. A single plastic pallet can last up to ten times longer than a wooden one. Reduced replacement frequency means fewer interruptions to supply chain operations and lower overall pallet expenditure.

Weather Resistance

Unlike wood, plastic does not absorb moisture and is not affected by humidity or extreme weather conditions. This ensures consistent performance in warehouses and during transportation, even in regions with challenging climates.

Standardization and Efficiency

Uniform Size and Shape

Plastic Pallets are manufactured with precision, resulting in uniform dimensions across large batches. This consistency improves stacking safety and allows for better space utilization in warehouses and transport containers. It also reduces the risk of product damage caused by uneven or unstable pallets.

Compatibility with Automation

As logistics systems increasingly rely on robotics and automation, the uniformity of Plastic Pallets has become a critical advantage. Automated systems, such as conveyors, robotic arms, and automated storage and retrieval systems, require precise pallet dimensions. Wooden pallets, which vary in size and may degrade, often disrupt automation. Plastic Pallets integrate seamlessly with these systems, improving efficiency and reducing downtime.

Load Stability

The consistent design of Plastic Pallets ensures even load distribution. This reduces the risk of shifting, tipping, or collapsing stacks, which enhances safety in warehouses and during transport.

Hygiene and Safety

Easy to Clean

Plastic Pallets are non-porous and resistant to water absorption, making them easy to wash and disinfect. This property makes them ideal for industries that require strict hygiene standards, such as food, beverage, pharmaceuticals, and healthcare.

Reduced Contamination Risks

Wooden pallets can harbor bacteria, fungi, or insects, which is a significant concern in sensitive industries. Plastic Pallets eliminate this risk, ensuring compliance with international regulations like FDA and EU food safety standards.

Worker Safety

Plastic Pallets are lighter and free from nails, splinters, or sharp edges that can cause injuries. Safer pallets contribute to fewer workplace accidents, less downtime, and improved employee well-being.

Space Optimization

Nestable and Stackable Designs

Many Plastic Pallets are designed to be nestable or stackable, allowing for efficient use of space in warehouses and during reverse logistics. Nestable pallets save storage space by fitting into one another when not in use, while stackable pallets maintain stability in storage and transport.

Lightweight Design

Plastic Pallets are generally lighter than their wooden counterparts, which reduces shipping costs and makes manual handling easier for workers. The balance between light weight and high strength supports logistics efficiency.

Sustainability Benefits

Longer Life Cycle

Because they last significantly longer than wooden pallets, Plastic Pallets reduce resource consumption and waste. Their extended service life contributes to lower environmental impact when used in closed-loop systems.

Recyclability

At the end of their service life, Plastic Pallets can be recycled into new pallets or other plastic products. Many manufacturers have take-back programs to ensure old pallets are collected and repurposed, contributing to a circular economy.

Reduced Need for Chemical Treatments

Wooden pallets often require chemical treatments to resist pests or mold, which can have environmental consequences. Plastic Pallets do not require such treatments, minimizing the release of harmful substances into the environment.

Industry Applications

Food and Beverage

Plastic Pallets are widely used in the food and beverage industry due to their hygienic properties. They can be easily cleaned and disinfected, preventing contamination of perishable goods.

Pharmaceuticals

The pharmaceutical industry relies on high levels of hygiene and traceability. Plastic Pallets ensure compliance with regulations and allow for easy integration with tracking systems such as RFID tags.

Automotive

In the automotive sector, Plastic Pallets are valued for their ability to handle heavy loads without breaking. Their durability supports efficient transport of parts across global supply chains.

Retail and E-Commerce

Plastic Pallets are ideal for retail and e-commerce warehouses that require fast turnover and integration with automated systems. Their uniformity and durability make them a natural fit for this dynamic industry.

Challenges to Consider

Higher Upfront Cost

The main challenge associated with Plastic Pallets is their higher initial investment compared to wood. However, the cost difference is offset by their longevity and lower replacement frequency.

Recycling Infrastructure

While Plastic Pallets are recyclable, proper recycling infrastructure is required to realize this benefit. In regions without established systems, disposal may still pose a challenge.

One-Way Exports

For one-way shipments, wooden pallets are often more economical, as they do not require return logistics. Plastic Pallets are best suited for closed-loop systems where they can be reused multiple times.

Future of Plastic Pallets in Logistics

Integration with Smart Technology

As supply chains evolve, Plastic Pallets are increasingly being embedded with RFID chips or sensors that enable real-time tracking. This enhances inventory management and improves supply chain visibility.

Growth of Sustainable Manufacturing

Manufacturers are experimenting with recycled plastics and bioplastics to produce more environmentally friendly pallets. This innovation will reduce reliance on fossil fuels and make Plastic Pallets an even more sustainable choice.

Global Adoption Trends

As industries embrace automation and sustainability goals, Plastic Pallets will continue to grow in adoption worldwide. From large-scale distribution centers to smaller logistics hubs, their advantages align with the future needs of global supply chains.

Conclusion

Plastic Pallets offer numerous advantages that make them an essential component of modern logistics. Their durability, uniformity, hygiene, and compatibility with automation improve efficiency across warehouses and transportation systems. They also provide sustainability benefits through longevity and recyclability. While the initial investment may be higher than wood, the long-term savings, operational efficiency, and environmental benefits make Plastic Pallets a superior choice for many industries. As supply chains continue to evolve, Plastic Pallets are poised to play an even greater role in creating efficient, safe, and sustainable logistics networks.

FAQ

Why are Plastic Pallets better than wood in logistics?

Because they are more durable, hygienic, uniform, and compatible with automated systems, making logistics more efficient.

Are Plastic Pallets more expensive than wood?

Yes, initially, but their long service life and reduced replacement costs make them more economical over time.

Can Plastic Pallets be recycled?

Yes, many are fully recyclable, and some manufacturers run closed-loop programs to repurpose old pallets into new ones.

Are Plastic Pallets safe for food and pharmaceuticals?

Yes, they meet international hygiene standards and are widely used in food and pharmaceutical industries.

Do Plastic Pallets save space in warehouses?

Yes, nestable and stackable designs help optimize storage and reduce space requirements.

Are Plastic Pallets lighter than wood?

Yes, most are lighter, reducing transportation costs and improving manual handling safety.

How do Plastic Pallets improve automation?

Their uniform dimensions allow them to integrate seamlessly with conveyors, robotic systems, and automated storage solutions.

What industries benefit most from Plastic Pallets?

Food, pharmaceuticals, automotive, retail, and e-commerce industries benefit greatly from their durability and hygiene.

What are the sustainability advantages of Plastic Pallets?

They last longer, reduce waste, and can be recycled, contributing to a circular economy.

Are Plastic Pallets suitable for one-way exports?

Not always, because of higher upfront costs. They are most effective in closed-loop systems where they are reused multiple times.

Table of Contents

- The Advantages of Using Plastic Pallets in Logistics

- Introduction to Plastic Pallets in Modern Logistics

- Durability and Longevity

- Standardization and Efficiency

- Hygiene and Safety

- Space Optimization

- Sustainability Benefits

- Industry Applications

- Challenges to Consider

- Future of Plastic Pallets in Logistics

- Conclusion

-

FAQ

- Why are Plastic Pallets better than wood in logistics?

- Are Plastic Pallets more expensive than wood?

- Can Plastic Pallets be recycled?

- Are Plastic Pallets safe for food and pharmaceuticals?

- Do Plastic Pallets save space in warehouses?

- Are Plastic Pallets lighter than wood?

- How do Plastic Pallets improve automation?

- What industries benefit most from Plastic Pallets?

- What are the sustainability advantages of Plastic Pallets?

- Are Plastic Pallets suitable for one-way exports?