ההתפתחות של פתרונות שרשרת האספקה המודרנית

תעשיית הלוגיסטיקה עשתה מהפכה מרשים בשנים האחרונות, כאשר משטחים מפלסטיק הופכים לאבן פינה בפעילות שרשרת האספקה. פתרונות אלו בתחום טיפול בחומרים שינו את הדרך בה עסקים מעבירים ואוגרים סחורות, ומציעים עמידות טובה יותר ויעילות עלות בהשוואה לחלופות המסורתיות. ככל שאנו מתקרבים לשנת 2025, הביקוש ל מטענים פלסטיים ממשיך לעלות, בשל יוזמות בתחום קיימות ודרישות של יעילות תפעולית.

מנהלי שרשראות אספקה ומומחים לרכש מזהים ביתר שאת כי השקעה במשטחי פלסטיק איכותיים מביאה ערך ארוך טווח והטבות תפעוליות. ההשקעה הראשונית מביאה לעיתים קרובות תמורה משמעותית באמצעות הפחתת עלויות החילוף, שיפור הבטיחות וקידום ביצועי שרשרת האספקה. חשוב להבין את התכונות והיתרונות המפתח של משטחי פלסטיק על מנת לקבל החלטות רכישה מושכלות בסביבה העסקית התחרותית של ימינו.

תכונות impres של משטחים מפלסטיק מודרניים

בניית חומרים מתקדמים

משטחים מפלסטיק של ימינו מיוצרים מפוליאתילן בצפיפות גבוהה (HDPE) או מפוליפרופילן, חומרים הנבחרים במתכוון בשל עמידותם וקשיותם הייחודית. פולימרים מתקדמים אלו מבטיחים שהמשטחים ישמרו על שלמותם המבנית גם תחת עומסים כבדים ותפעול תכוף. בניגוד למשטחים מעץ מסורתיים, משטחים מפלסטיק עמידים בפני קריעות, צמיחה בקטריאלית וספיגת לחות, מה שעושה אותם אידיאליים לתעשיות רבות, כולל תעשיות המזון והתרופות.

תהליך הייצור כולל טכניקות דפוס מתקדמות שיוצרות עיצוב חד-חלקי ללא הרכבות. זה מסיר נקודות חולשה וחיבורים הנמצאים לרוב במשטחים מעץ, ומייצר מוצר אמין וארוך-חיים יותר. הרכב החומר מאפשר גם מידות ומשקלים אחידים, שחשובים במיוחד למערכות טיפול אוטומטיות וניהול מלאי.

Лементי תכנון חדשניים

משטחי פלסטיק מודרניים כוללים עיצובים ארגונומיים המשפרים את יעילות הטיפול והבטיחות. שילוב משטחים נגד החלקה וקצוות מחוזקים מפחית את הסיכון לנזק למוצר במהלך ההובלה. דגמים רבים כוללים דפוסי אחיזה מיוחדים המונעים תזוזת עומס ומספקים יציבות טובה יותר במהלך פעולות מלגזה.

חדשנות בעיצוב מתרחבת גם לתחתית המשטח, שבה צלעות חיזוק אסטרטגיות מפזרות את המשקל באופן אחיד ומונעות עיוות תחת עומס כבד. חלק מהדגמים כוללים עיצוב קיבועי (nesting) המאפשרים ניצול מיטבי של שטח אחסון כאשר הם ריקים, ובכך פותרים אתגר נפוץ בפעולות לוגיסטיקה הפוכה.

יתרונות וטובת הניהול

השגת יעילות גבוהה יותר슬 שרשרת אספקה

יישום משטחי פלסטיק בפעולות שרשרת האספקה מביא לשיפורים מוחשיים ביעילות. הממדים המתואמים והמשקל הקל יותר תורמים לתכנון טעינה מדויק יותר וצורך דלק מופחת במהלך התחבורה. העמידות של משטחי פלסטיק משמעותה צורך פחות בהחלפות ופחות זמן שקט עקב בעיות הקשורות למשטחים.

המשטח החלק והחופשי מקנים של פלסטיק מאפשר טיפול קל יותר וסיכון מופחת לנזק למוצרים. עובדה זו חשובה במיוחד במגדלי אוטומטיים שבהם איכות משטחים עקביות היא חיונית לצורך אמינות המערכת. הביצועים היציבים של משטחי פלסטיק מסייעים באופטימיזציה של תהליכי הטיפול בחומרים ומפחיתים את צורכי התפעול והתחזוקה של ציוד הטיפול.

עלות-יעילות לאורך זמן

בעוד ההשקעה הראשונית במשטחים מפלסטיק עשויה להיות גבוהה יותר מאלטרנטיבות עץ מסורתיות, היתרונות הפיננסיים לטווח הארוך הם משמעותיים. אורך החיים הממושך שלהם, שغالבא עולה על 100 נסיעות בהשוואה ל-15-20 עבור משטחי עץ, תורם לייתר עלות נמוכה יותר לשימוש. בנוסף, משטחים מפלסטיק מבטלים הוצאות הקשורות להסרת מסמרים, החלפת לוחות ופינוי משטחי עץ פגומים.

הפחתה בנזקי מוצרים ושיפור הבטיחות במקום העבודה תורמים לחיסכון משמעותי בעלויות. דמי ביטוח עשויים לרדת עקב הסיכון הנמוך יותר לפציעה ואיבוד מוצרים. אפשרות המחזור של משטחי פלסטיק גם כן מעניקה ערך בסוף מחזור החיים שלהם, ותומכת ביוזמות כלכלה מחזורית.

תקינות ותפוקה סביבתית

מדדי ביצועים סביבתיים

משטחים מפלסטיק תורמים ליציבות הסביבתית בזכות מחזור חיים ארוך ויכולת 재צycling. כששמורים בהם טוב, הם יכולים להישאר בשימוש לאורך שנים רבות, מה שמצמצם את הביקוש לייצור חדש ולצריכת המשאבים הקשורה אליו. היכולת להפוך את המשטחים האלה למוצרי מחזור בסוף תקופת השימוש שלהם יוצרת מערכת סגורה שמצמצמת פסולת.

משטחים מפלסטיק מודרניים מיוצרים ביתרה רבה יותר מחלקים משומשים, מה שפוחת עוד יותר את ההשפעה הסביבתית שלהם. עמידותם בפני לחות וכהלים מבטלת את הצורך בטיפולים מזיקים הנדרשים למשטחים מעץ, כגון פיחות ברומיד 메틸 או חומרים משמרים כימיים.

התאמהתאם רגולטורי ותקנים

ייצור משטחים מפלסטיק עומד בדרישות חמורות של תקנים סביבתיים ועסקיים. זה כולל עמידה בדרישות של בקרת חומרים מזון, דרישות עמידות בכימיקלים ותקני בטיחות אש. תהליך הייצור המבוקר מבטיח איכות עקבות קבועה, גורמים חשובים לעסקים הפועלים בתעשייה נצרכת.

במגמת החמרה של הרגולציה הסביבתית, משטחים מפלסטיק מציעים פתרון עתידי המתאים או עולה על דרישות התאמה. טבעם שאינו סופג מונע זיהום ומקל את הליכי הניקיון, ותומך בדרישות ההיגיינה ביישומים רגישים.

קריטריוני בחירה והיבטים לקנייה

דרישות ספציפיות ליישום

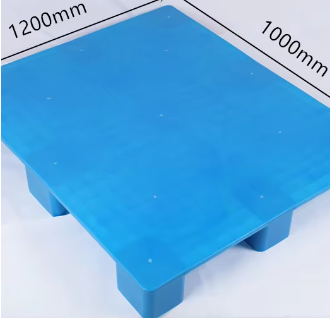

בחירת משטח פלסטיק מתאים דורשת שיקול דעת של צורכי היישום הספציפיים. גורמים כגון עמידות במשקל, שיטת טיפול, תנאי אחסון ודרישות תחבורה צריכים להנחות את תהליך הבחירה. ייתכן ויש יישומים שיתרמו מתכונות מיוחדות כמו תוספי עיכוב להבה או זיהוי מתכת בסביבות עיבוד מזון.

הסביבה التشغית ממלאה תפקיד חשוב בבחירת המשטחים. טמפרטורות קיצוניות, חשיפה לכימיקלים ואסטרטגיות ניקיון עלולות להשפיע על ביצועי המשטח. הבנת הגורמים הללו עוזרת להבטיח שמשטח הפלסטיק הנבחר עומד בדרישות התפעול תוך כדי מירב תשואת ההשקעה.

ניתוח עלויות הכוללות

ניתוח עלות מקיף צריך לקחת בחשבון יותר רק את מחיר הרכישה. גורמים כגון תוחלת חיים צפויה, דרישות תחזוקה, יעילות בתפעול וערך בסוף מחזור החיים תורמים לעלות הכוללת של בעלות. הניתוח צריך גם להתחשב בחיסכון פוטנציאלי בתחומים כמו נזק מופחת למוצרים, שיפור ביטחון העובדים ו lowered chirot ביטוח.

השקעה במשטחים מפלסטיק איכותיים לרוב מביאה ערך טוב יותר לאורך זמן בהשוואה לבחירה באפשרויות זולות יותר. עמידות ומאפייני הביצועים של משטחים מפלסטיק איכותיים מוצדקים בדרך כלל את העלות ההתחלתית הגבוהה יותר בזכות אורך שירות ממושך ובעיות תפעוליות מופחתות.

שאלות נפוצות

מהי תוחלת החיים הטיפוסית של משטחי פלסטיק?

משטחי פלסטיק איכותיים יכולים לשרת יותר מ-100 נסיעות בתנאי תפעול רגילים. אורך החיים שלהם תלוי בגורמים כגון שיטות הטיפול, סוגי המטענים והתנאים הסביבתיים. עם תחזוקה נכונה וטיפול זהיר, חברות רבות מדווחות על משך חיים של יותר מעשר שנים.

האם משטחי פלסטיק מתאימים לאחסון בחוץ?

משטחי פלסטיק הם אידיאליים לאחסון בחוץ הודות לעמידותם בפני מזג אוויר, קרינת UV ולחות. בניגוד למשטחים עציים, הם לא ירקבו, יתעוותו או יתקלקלו עקב חשיפה לאלמנטים. עם זאת, חשוב לבחור במשטחים עם יציבי UV לשימוש ממושך בחוץ.

מהן כושרות העומס שמשטחי פלסטיק יכולים לשאת?

משטחי פלסטיק מודרניים זמינים בדרגות עומס שונות, שמתבטאות בדרך כלל בין 1,500 ל-5,000 פאונד במשקל סטטי. כושר העומס הדינמי נמוך יותר באופן כללי ותלוי בעיצוב המשטח ובשימוש אליו הוא מיועד. חשוב לבחור במשטחים בעלי דירוג מתאים הן לצורך העומס הסטטי והן לדינמי בתפעול שלך.

האם ניתן להחזיר משטחי פלסטיק לסבך בסוף תקופת השימוש?

כן, משטחי פלסטיק ניתנים לסיבוך מלא בסוף תקופת השירות. יצרנים רבים מציעים תוכניות החזר או שירותי סיבוך. החומרים יכולים לעבור עיבוד ולהישמש לייצור משטחים חדשים או מוצרים פלסטיים אחרים, ובכך לתמוך בעקרונות של עמידות וכלכלה מעגלית.