Choosing between plastic and wood pallets represents one of the most critical decisions in modern warehouse and logistics operations. The debate surrounding plastic pallet versus wooden alternatives has intensified as businesses seek cost-effective, sustainable solutions that align with operational efficiency goals. Understanding the fundamental differences between these two materials can significantly impact your bottom line, storage capabilities, and long-term business strategy.

Modern supply chain management demands materials that deliver consistent performance while minimizing operational disruptions. The choice between plastic and wooden pallets affects everything from product protection to regulatory compliance, making this decision far more complex than simple cost comparison. Industry leaders increasingly recognize that pallet selection influences warehouse efficiency, product damage rates, and environmental sustainability metrics.

Both plastic and wooden pallets serve essential functions in material handling, yet they offer distinctly different advantages depending on specific operational requirements. Factors such as load capacity, durability, hygiene standards, and lifecycle costs create a multifaceted evaluation process that requires careful consideration of immediate needs versus long-term operational goals.

Material Composition and Manufacturing Differences

Plastic Pallet Construction Technology

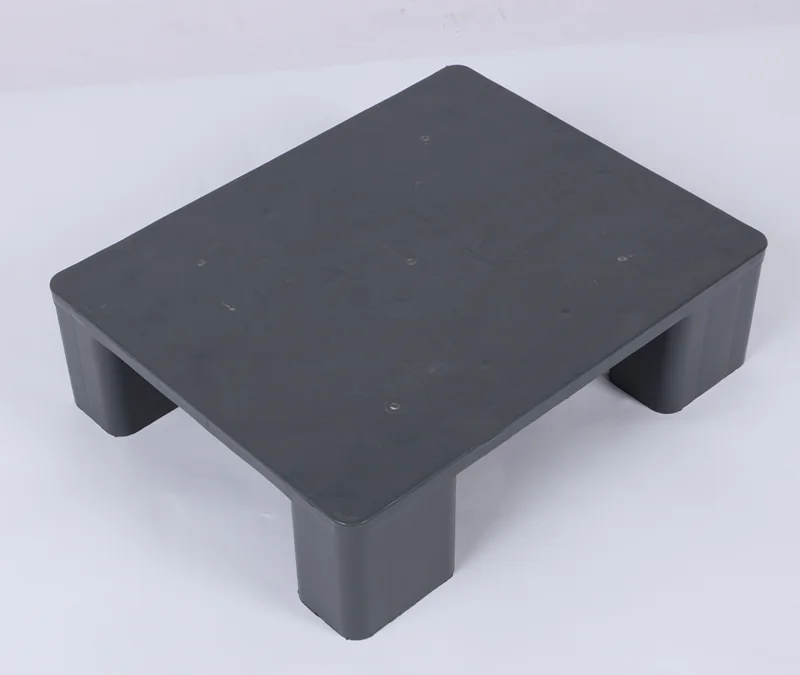

Modern plastic pallets utilize advanced polymer technology, primarily incorporating high-density polyethylene (HDPE) or polypropylene materials that provide exceptional structural integrity. The manufacturing process involves injection molding or structural foam molding, creating seamless designs that eliminate weak points common in traditional construction methods. These manufacturing techniques enable precise dimensional control, ensuring consistent performance across large quantities.

The molecular structure of plastic pallet materials offers inherent resistance to moisture, chemicals, and biological degradation. Unlike organic materials, plastic pallets maintain their structural properties regardless of humidity levels or temperature fluctuations within normal operating ranges. This stability translates to predictable performance characteristics that warehouse managers can rely upon for consistent operational planning.

Advanced plastic formulations incorporate additives that enhance specific performance characteristics, such as UV stabilizers for outdoor applications or antimicrobial compounds for food-grade requirements. These engineered properties allow manufacturers to customize plastic pallets for specialized applications while maintaining the core benefits of plastic construction.

Traditional Wood Pallet Manufacturing

Wooden pallets traditionally utilize hardwood or softwood lumber, assembled using mechanical fasteners such as nails or screws. The construction process involves cutting lumber to specific dimensions, followed by assembly using standardized designs that prioritize cost-effectiveness over advanced engineering principles. This approach results in pallets with natural variations in strength and durability based on wood quality and construction techniques.

Wood pallet manufacturing relies heavily on forestry resources, creating supply chain dependencies that can affect availability and pricing. Seasonal variations in lumber quality, moisture content, and regional availability impact the consistency of wooden pallet performance. Additionally, wood treatment processes for international shipping compliance add complexity and cost to the manufacturing process.

The organic nature of wood creates inherent limitations in terms of dimensional stability and resistance to environmental factors. Wooden pallets naturally expand and contract with moisture changes, potentially affecting load stability and storage efficiency over time. These characteristics require ongoing maintenance and replacement considerations that impact total cost of ownership calculations.

Durability and Lifespan Comparison

Plastic Pallet Longevity Factors

The exceptional durability of plastic pallets stems from their resistance to common deterioration factors that affect traditional materials. Unlike wood, plastic pallets do not absorb moisture, preventing warping, splitting, or dimensional changes that compromise structural integrity. This resistance to environmental factors enables plastic pallet solutions to maintain consistent performance for years under normal operating conditions.

Testing data demonstrates that quality plastic pallets can withstand thousands of handling cycles without significant degradation in load-bearing capacity or structural stability. The absence of organic materials eliminates concerns about insect damage, fungal growth, or bacterial contamination that commonly affect wooden alternatives. This biological resistance translates to extended service life and reduced replacement frequency.

Impact resistance represents another significant advantage of engineered plastic construction. While wooden pallets may crack or splinter under stress, plastic pallets typically demonstrate elastic deformation that allows recovery from minor impacts. This resilience reduces damage-related downtime and maintains operational continuity in demanding warehouse environments.

Wood Pallet Lifecycle Considerations

Wooden pallets face multiple deterioration factors that limit their operational lifespan compared to engineered alternatives. Moisture absorption leads to dimensional instability, creating gaps or warping that affects load distribution and stacking stability. Regular exposure to humidity cycles accelerates wood degradation, particularly in outdoor or uncontrolled storage environments.

Mechanical damage accumulates more rapidly in wooden construction due to the grain structure and fastener-dependent assembly. Nail loosening, board cracking, and splinter formation create safety hazards while reducing load capacity over time. These degradation patterns require ongoing inspection and maintenance programs to ensure safe operation.

The organic composition of wood pallets makes them susceptible to pest infestation and biological contamination, particularly in food-grade applications. Treatment requirements for international shipping add complexity while potentially introducing chemical residues that affect product compatibility. These factors contribute to shorter effective service life and higher replacement rates compared to synthetic alternatives.

Cost Analysis and Return on Investment

Initial Investment Considerations

The upfront cost differential between plastic and wooden pallets represents the most visible factor in purchasing decisions, yet this comparison requires careful analysis of long-term value propositions. While plastic pallets typically command higher initial prices, their extended lifespan and reduced maintenance requirements often justify the investment through improved total cost of ownership calculations.

Volume purchasing considerations significantly impact the cost analysis for both pallet types. Wooden pallets benefit from established manufacturing infrastructure and commodity pricing, while plastic pallets leverage economies of scale in polymer processing and tooling amortization. Understanding these cost structures helps businesses negotiate favorable pricing based on projected volume requirements.

Regional availability affects pricing dynamics for both materials, with transportation costs influencing the delivered price advantage. Local lumber availability may favor wooden pallets in certain markets, while plastic manufacturing concentration can create shipping cost penalties in remote locations. These geographic factors require location-specific cost analysis for accurate comparison.

Long-term Financial Impact

Lifecycle cost analysis reveals significant differences between plastic and wooden pallet ownership expenses beyond initial purchase price. Plastic pallets typically demonstrate lower total cost of ownership through reduced replacement frequency, minimal maintenance requirements, and consistent performance characteristics that prevent operational disruptions.

Maintenance and repair costs favor plastic construction due to the absence of mechanical fasteners and organic degradation factors. Wooden pallets require ongoing inspection, board replacement, and fastener tightening to maintain safe operation, while plastic pallets maintain structural integrity with minimal intervention. These maintenance savings compound over time, significantly affecting operational budgets.

End-of-life value considerations also impact the financial equation, with plastic pallets offering recycling value that wooden alternatives cannot match. Plastic materials retain inherent value for reprocessing into new products, while damaged wooden pallets typically become waste disposal expenses. This residual value contributes to improved return on investment calculations for plastic pallet programs.

Hygiene and Safety Standards

Sanitation and Cleanliness Requirements

Food-grade and pharmaceutical applications demand stringent hygiene standards that significantly favor plastic pallet construction over traditional wood alternatives. The non-porous surface of plastic pallets prevents bacterial growth and contamination absorption while enabling thorough cleaning and sanitization protocols. This cleanability ensures compliance with HACCP, FDA, and other regulatory requirements governing food safety.

Chemical resistance properties of plastic pallets enable the use of industrial cleaning agents and sanitizers without material degradation or contamination concerns. Unlike wood, which can absorb cleaning chemicals and create residue issues, plastic surfaces maintain their integrity while allowing complete removal of cleaning agents. This compatibility supports automated washing systems and rigorous sanitation schedules.

The seamless construction of molded plastic pallets eliminates crevices and joints where contaminants can accumulate, a significant advantage over nailed wooden construction. Smooth surfaces facilitate visual inspection and cleaning verification, supporting quality assurance programs in regulated industries. These design characteristics directly contribute to product safety and regulatory compliance.

Workplace Safety Considerations

Employee safety improvements represent a significant advantage of plastic pallet implementation, particularly regarding splinter elimination and weight-related injury prevention. Wooden pallets create ongoing splinter hazards that can cause cuts and puncture wounds, while plastic alternatives maintain smooth surfaces throughout their service life. This safety improvement reduces workers' compensation claims and supports positive workplace culture.

The consistent weight distribution and handling characteristics of plastic pallets contribute to ergonomic improvements in manual handling operations. Unlike wooden pallets, which may have uneven weight distribution due to moisture content variations, plastic pallets provide predictable handling properties that reduce strain and injury risk. This consistency supports proper lifting techniques and reduces repetitive stress injuries.

Fire safety considerations vary between materials, with plastic pallets offering controlled burn characteristics compared to the unpredictable combustion patterns of wood. While both materials require appropriate fire suppression systems, plastic pallets typically produce less smoke and toxic emissions during combustion. These safety characteristics support comprehensive risk management strategies in warehouse operations.

Environmental Impact and Sustainability

Resource Utilization and Renewable Factors

Environmental considerations present complex tradeoffs between renewable wood resources and recyclable plastic materials. Wooden pallets utilize renewable forestry resources that can be sustainably harvested, supporting carbon sequestration during tree growth phases. However, the short lifespan and disposal challenges of wooden pallets often negate these environmental benefits through accelerated replacement cycles.

Sustainable forestry practices can minimize the environmental impact of wooden pallet production, yet the reality of global supply chains often involves less rigorous environmental standards. Deforestation concerns and habitat disruption associated with lumber harvesting create significant environmental consequences that must be weighed against the renewable nature of wood resources.

Plastic pallet production relies on petroleum-based feedstocks, creating initial environmental concerns regarding fossil fuel consumption. However, the extended lifespan of plastic pallets distributes this environmental cost over significantly more usage cycles compared to wooden alternatives. Additionally, advances in bio-based plastics and recycled content integration are improving the environmental profile of plastic pallet manufacturing.

End-of-Life and Recycling Options

Recycling capabilities strongly favor plastic pallets due to the established infrastructure for thermoplastic reprocessing and the inherent value of clean plastic materials. Damaged or worn plastic pallets can be ground and reprocessed into new pallets or alternative products, creating a true circular economy model. This recyclability prevents waste generation while recovering material value at end-of-life.

Wooden pallet disposal options include biomass energy generation, mulch production, or landfill disposal, depending on treatment chemicals and contamination levels. International shipping pallets treated with chemical preservatives may require special disposal procedures, adding cost and complexity to waste management. These disposal challenges often result in landfill placement rather than beneficial reuse.

Carbon footprint analysis must consider the complete lifecycle from raw material extraction through disposal or recycling. While wooden pallets sequester carbon during growth, their short lifespan and disposal emissions often create net carbon generation. Plastic pallets demonstrate lower lifecycle carbon emissions through extended use phases and recycling recovery, despite higher initial production emissions.

FAQ

What is the typical lifespan difference between plastic and wooden pallets

Plastic pallets typically last 10-15 years under normal warehouse conditions, while wooden pallets average 2-3 years before requiring replacement. The extended lifespan of plastic pallets results from their resistance to moisture, biological degradation, and mechanical wear factors that limit wooden pallet durability. This lifespan difference significantly impacts total cost of ownership calculations and replacement scheduling requirements.

Are plastic pallets suitable for outdoor storage applications

Yes, plastic pallets excel in outdoor storage environments due to their resistance to weather-related deterioration. Unlike wooden pallets that absorb moisture and experience dimensional changes, plastic pallets maintain structural integrity regardless of humidity, temperature fluctuations, or precipitation exposure. UV-stabilized formulations prevent degradation from sunlight exposure, making plastic pallets ideal for outdoor applications.

How do load capacities compare between plastic and wooden pallets

Both plastic and wooden pallets can achieve similar load capacities when properly engineered, typically supporting 2,000-4,000 pounds in standard configurations. However, plastic pallets maintain consistent load capacity throughout their service life, while wooden pallets may experience capacity reduction due to moisture content changes, fastener loosening, or structural degradation. This consistency makes plastic pallets more reliable for automated systems and precise load calculations.

Which pallet type offers better compatibility with automated warehouse systems

Plastic pallets demonstrate superior compatibility with automated material handling systems due to their dimensional consistency, smooth surfaces, and absence of protruding fasteners. The uniform construction eliminates variations that can disrupt automated conveyors, sorters, or robotic systems. Additionally, the durability of plastic pallets reduces maintenance-related downtime in automated facilities where equipment reliability is critical for operational efficiency.